Tube heat exchangers

Depending on the purpose of use and conditions, we design and manufacture different types of tube heat exchangers for different media, for demanding processes and conditions. Tube heat exchangers are easy to clean and have low pressure losses.

We manufacture heat exchangers for the following applications, among others: heaters, coolers, condensers, boilers and vaporizers. The structural options we deliver include, among others:

- U-tube heat exchangers

- Fixed shell heat exchangers

- Heat exchangers with floating ends

- Special applications

The design and manufacture of tube heat exchangers is our special area of expertise. Our know-how provides working heat transfer solutions even for demanding or even special applications. In design and manufacturing, we comply with the requirements of the TEMA (Tubular Exchanger Manufacturer Association) standard. In addition to TEMA, design and manufacturing are implemented using some of the following standards:

- EN 13445

- ASME VIII div.1

- AD-2000 MERKBLATT

In addition to complete heat exchangers, we offer installation, maintenance, and modification services for the entire life cycle of the heat exchanger. We also offer modernization and renovation solutions, in which extensive wholes as well as individual components, such as groups of pipes, chambers or shell parts, are renewed for existing pipe heat exchangers.

We do the design, calculation and thermotechnical dimensioning of the heat exchangers ourselves in accordance with the customer’s requirements. Thermotechnical dimensioning is done on the basis of process parameters, taking into account internal and external loads, flow rates, materials, cleanability and vibrations.

The construction material of the heat exchanger is always selected according to the application. Things that influence the choice are e.g. the risk of corrosion or erosion caused by the contents, pressure and temperature.

The high quality of the production is partially guaranteed by our modern and efficient production. An example of this is semi-automatic TIG orbital welding, which enables the fast, efficient and uniform production of a group of pipes. Our production has an automatic powder arc/MIG-MAG hybrid welding station, which makes it easy to implement larger and more challenging projects. Our personnel is competent, experienced and committed to high quality standards.

In project deliveries, we emphasize punctuality, careful documentation of the project and keeping the customer informed about the progress of the project.

Our customers trust us as a supplier of equipment, experts in strength calculation, design and thermodynamics, implementers of innovative and functional solutions, and professionals in demanding welding. We invest in welding quality management. Our delivery projects are carefully documented, and we pay particular attention to sticking to schedules and keeping the customer informed about the progress of the project.

- Pressure equipment in accordance with Directive 2014/68/EU

- With the Refinec project management system, the customer always stays up to date

Our scope of delivery includes:

- Design of devices based on initial data provided by the customer

- Strength calculation

- If necessary, FEM calculation and flow modeling

- Thermodynamic sizing calculations and vibration analyses

- Structural dimensioning

- Work drawings

- Pressure equipment documentation

All our welders are qualified according to the latest ISO standards. All our welding instructions are approved by method tests according to ISO standards.

Construction materials, the use of which we have solid know-how:

- Austenitic steels: AISI 304L, AISI 316L, AISI 310S, AISI 321H

- Super austenitic steels: 904L and 254 SMO

- Duplex and superduplex steels: EN 1.4162, EN 1.4462, EN 1.4410

- Nickel alloys: Hastelloy C-276, Inconel 625, Monel 400

- Carbon steels: P235GH, P265GH, P275NH/-NL1/-NL2, P355NH/-NL1/-NL2

- Carbon steels + special requirements: CS-HIC and LTCS

- Heat-resistant steels: 13CrMo4-5, 10CrMo9-10, X16CrMo5-1, X11CrMo5

- Titans: Gr.2 and Gr.7

Pressure vessels

We manufacture and design pressure vessels and pressure equipment according to EN 13445, ASME VIII div.1 or AD-2000 MERKBLATT standards, adapted to needs.

Our experts are familiar with the Pressure Equipment Act, the directive and various regulations as well as their requirements. A well-designed and high-quality manufactured pressure device is safe, durable and reliable.

We also supply standard solutions from the compressed air tank.

Our customers trust us as a supplier of equipment, as an expert in strength calculation and design, as an implementer of innovative and functional solutions, and as professionals in demanding welding. We invest in welding quality management. Our delivery projects are carefully documented, and we pay particular attention to keeping to the schedules and keeping the customer aware of the progress of the project.

In manufacturing, we constantly invest in modern manufacturing methods to achieve the highest possible quality combined with efficient production. An example of this is the automatic powder arc/MIG-MAG hybrid welding station that is already in use, which makes it easy to implement larger and more challenging projects.

- Pressure equipment in accordance with directive 2014/68/EU

- With the help of the Refinec project management system, the customer stays up-to-date

Our scope of delivery includes:

- Design of devices based on initial data provided by the customer

- Strength calculation

- If necessary, FEM calculation and flow modeling

- Structural dimensioning

- Working drawings

- Pressure equipment documentation

- All our welders are qualified according to the latest ISO standards. All our welding instructions are approved by method tests according to ISO standards.

Construction materials, the use of which we have solid know-how:

- Austenitic steels: AISI 304L, AISI 316L, AISI 310S, AISI 321H

- Super austenitic steels: 904L and 254 SMO

- Duplex and superduplex steels: EN 1.4162, EN 1.4462, EN 1.4410

- Nickel alloys: Hastelloy C-276, Inconel 625, Monel 400

- Carbon steels: P235GH, P265GH, P275NH/-NL1/-NL2, P355NH/-NL1/-NL2

- Carbon steels + special requirements: CS-HIC and LTCS

- Heat-resistant steels: 13CrMo4-5, 10CrMo9-10, X16CrMo5-1, X11CrMo5

- Titans: Gr.2 and Gr.7

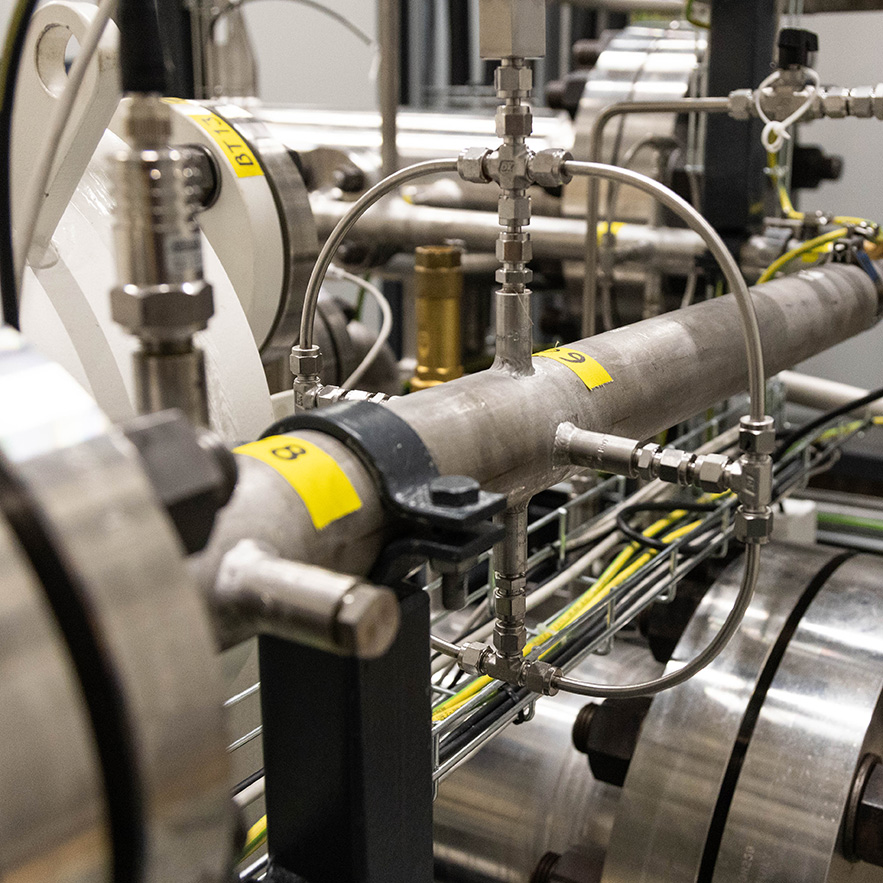

Other pressure equipment

We manufacture all kinds of other pressure equipment to order, including:

- Filters and separators

- Fire hydrants

- Various pressure devices for research facilities

We manufacture and design pressure vessels and pressure equipment in accordance with EN 13445, ASME VIII div.1 or AD-2000 MERKBLATT standards.

We have long experience and knowledgeable experts with extensive experience who know the Pressure Equipment Act, directives, various regulations and their requirements. By following them, pressure equipment is made safe, durable and reliable.

Our customers trust us as a supplier of equipment, as an expert in strength calculation, design and thermodynamics, as an implementer of innovative and functional solutions, and as professionals in demanding welding. We invest in welding quality management. Our delivery projects are carefully documented, and we pay particular attention to keeping to the schedules and keeping the customer aware of the progress of the project.

In manufacturing, we constantly invest in modern manufacturing methods to achieve the highest possible quality combined with efficient production. Examples of this are the orbital welding system already in use and the automatic powder arc/MIG-MAG hybrid welding station, which enables the implementation of larger and more challenging projects.

- Pressure equipment in accordance with directive 2014/68/EU

- With the help of the Refinec project management system, the customer stays up-to-date

Our scope of delivery includes:

- Design of devices based on initial data provided by the customer

- Strength calculation

- If necessary, FEM calculation and flow modeling

- Thermodynamic sizing calculations and vibration analyses

- Structural dimensioning

- Working drawings

- Pressure equipment documentation

All our welders are qualified according to the latest ISO standards. All our welding instructions are approved by method tests according to ISO standards.

Construction materials, the use of which we have solid know-how:

- Austenitic steels: AISI 304L, AISI 316L, AISI 310S, AISI 321H

- Super austenitic steels: 904L and 254 SMO

- Duplex and superduplex steels: EN 1.4162, EN 1.4462, EN 1.4410

- Nickel alloys: Hastelloy C-276, Inconel 625, Monel 400

- Carbon steels: P235GH, P265GH, P275NH/-NL1/-NL2, P355NH/-NL1/-NL2

- Carbon steels + special requirements: CS-HIC and LTCS

- Heat-resistant steels: 13CrMo4-5, 10CrMo9-10, X16CrMo5-1, X11CrMo5

- Titans: Gr.2 and Gr.7

Process tanks

We design and manufacture mixing tanks and other process tanks according to the process values required by the customer.

Our customers trust us as a supplier of equipment, as an expert in strength calculation and design, as an implementer of innovative and functional solutions, and as professionals in demanding welding. We invest in welding quality management. Our delivery projects are carefully documented, and we pay particular attention to keeping to the schedules and keeping the customer aware of the progress of the project.

In manufacturing, we constantly invest in modern manufacturing methods to achieve the highest possible quality combined with efficient production.

Our scope of delivery includes:

- Design of devices based on initial data provided by the customer

- Strength calculation

- If necessary, FEM calculation and flow modeling

- Structural dimensioning

- Working drawings

All our welders are qualified according to the latest ISO standards. All our welding instructions are approved by method tests according to ISO standards.

Construction materials, the use of which we have solid know-how:

- Austenitic steels: AISI 304L, AISI 316L, AISI 310S, AISI 321H

- Super austenitic steels: 904L and 254 SMO

- Duplex and superduplex steels: EN 1.4162, EN 1.4462, EN 1.4410

- Nickel alloys: Hastelloy C-276, Inconel 625, Monel 400

- Carbon steels: P235GH, P265GH, P275NH/-NL1/-NL2, P355NH/-NL1/-NL2

- Carbon steels + special requirements: CS-HIC and LTCS

- Heat-resistant steels: 13CrMo4-5, 10CrMo9-10, X16CrMo5-1, X11CrMo5

- Titans: Gr.2 and Gr.7